Wafer Check Valves

For over 30 years, TVI Valves has been providing high-quality valves and accessories to clients across a diverse range of industries. Our commitment to excellent customer service combined with global partnerships with top valve manufacturers allows us to deliver quality valve solutions with quick turnaround times. Included in our selection of available valve products are wafer check valves.

Wafer Check Valves from TVI Valves

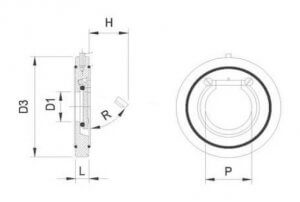

At TVI Valves, we provide high-quality thermoplastic wafer check valves that allow for optimal unidirectional flow through a fluid system. The molded body allows the swinging disc seated in the valve to fully open and close throughout operations to create a fast, responsive seal. Each of our wafer check valves is designed to take up minimal space, especially in applications where flanged check valves won’t fit. The valves feature a simple but effective design consisting of:

- A body or seat made from PVC, PP, CPVC, or PVDF

- A flapper made from PVC, PP, CPVC, or PVDF

- A flapper mounting screw made from PP

- An O-ring made from EPDM or Viton for a tight, reliable installation seal

- An installation device made from 316 stainless steel

- Optional spring assist mechanism made from 316 stainless steel

- Optional spacer

The design of our wafer check valves allows for vertical or horizontal operation, and the thermoplastic construction materials offer resistance to corrosion and chemical damage for long-lasting, durable performance. Our wafer check valves range in size from 1 1/2″ to 20″, and the wafer body fits between flanges with standard ANSI dimensions.

Our wafer check valves are ideal for use in the following industries:

- Chemical

- Environmental

- Processing

- Systems Engineering

- Water and Waste Treatment

What Is a Wafer Check Valve?

Wafer check valves are thin, thermoplastic valves that utilize a swinging disc to block or allow fluid flow. When fluid flows from one direction, the disc lifts off the seat and allows fluid through. When fluid flows in the opposite direction, the disc closes and creates a seal to prevent fluid backflow. Wafer check valves can be augmented with spring and lever mechanisms for faster closing times, which helps reduce damage from water hammer. Check valves are crucial components for ensuring unidirectional fluid flow.

The thin design of wafer check valves makes them ideal for use in compact, small pipe systems that can only accommodate valves with short takeout lengths. Their short length also reduces the risk of clogging, making them suitable for systems that transport solids and semi-solids.

How to Install a Wafer Check Valve

Wafer check valves are simple to install. To start, users need to orient the wafer check valve so that the seated disc opens in the same direction as fluid flow. Then users can install the valve between the block flange (the source of the fluid) and the latter flanges of the system. Each of our valves fits between ANSI B16.5 Class 150 flanges. Some wafer check valves require spacers (such as wafer check valves between 2 1/2″ and 3″), so our team can help you choose the right model and configuration for your system.

While the actual installation process is simple, installing it in the wrong direction can cause critical damage to your system and even damage the gears in your pump head. Ensure the valve is installed in the correct orientation before returning to normal operations.

Contact TVI Valves Today

The right wafer check valve can stop backflow in your fluid system without the large space demands of flange check valves. At TVI Valves, we specialize in finding and supplying the right check valves for any industrial system, no matter how unique or complex. Contact us today to find the solution to your facility’s valve needs.